Automations & packaging tecnologies since 1978

Structure of the production process

Business organization of Corti Domenico S.r.l.

department

Mechanical

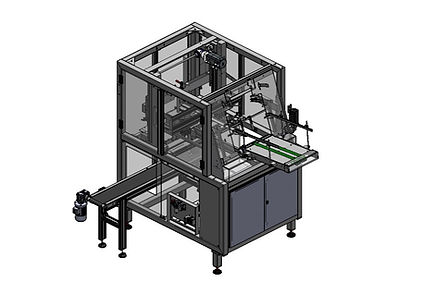

Design

Internal 3D design

Drafting

Manuals

Compliance with current directives

Revamping (modernization)

department

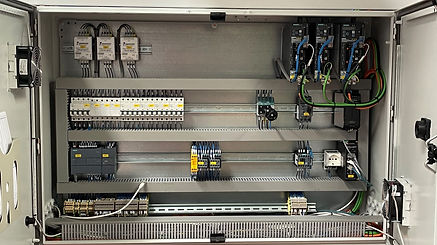

Electricall and

Pneumatic Design

Electric / pneumatic diagram

Components Siemens, Asem, Balluff, Festo, SMC

Revamping (modernization)

department

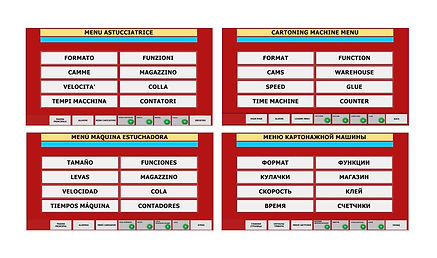

Software

Design

Industry 4.0

Internal customized programming

Teleassistance service

Robotics

Internal processing with CNC machining centers and carbon 3D printing

Technical assistance service

Revamping (modernization)

Internal processing

Technical assistance service

Revamping (modernization)

Various Administrative

Departments

Administration

Purchases

Commercial

Marketing

Company history

1904 The Beginning - Nails Production.

Domenico Corti founded The Corti Domenico Metallurgica to produce nails. His son Osvaldo Corti, representing the second generation, developed the family business with further investment.

1978 Packaging for Fasteners.

Domenico Corti representing the third generation converted the company by renaming it as "Corti Domenico" and dedicated it to the design and construction of automatic packaging lines for fasteners.

1995 The Fourth Generation.

Osvaldo Corti representing the fourth generation joined the company and facilitated new ideas and a new approach to foreign markets.

1997 Packaging of Cosmetic Products.

Beginning of the design and construction of machines and automatic packaging lines for the cosmetic sector.

2008 Packaging for Pharmaceutical Industry.

Beginning the design and construction of machines and automatic packaging lines for the pharmaceutical sector.

2012 Automation.

Beginning of the design and construction of special machines and lines for various purposes: assembly, robotics, vision, etc.

2018. Investments in staff and machines.

Expansion of the organizational structure with managers and assistants for mechanical design, software design, internal production of mechanical components.

Purchase of new machinery for the storage of materials (vertical warehouses for storage of aluminum bars and for components ready to be assembled).

2019. Collaborative robotics

Start of the O.E.M. with insertion of a dedicated programmer technician.

2020. 3D printing.

3D printer with double fuser for the use of Onyx in combination with carbon fiber (long fiber), glass fiber, Kevlar.

2021. New offices for mechanical and software design.

Wire processing.

Since 1987 the representation of the company "The Itaya Engineering Ltd." of Tokyo (Japan) which designed the first CNC machine in the world for the production of springs (for the Italian, Portuguese, Spanish, Greek, Russian markets).

Since 2016 the representation for the Italian, Portuguese, Russian and Spanish markets of the company "T. Butler Engineering Ltd." of Fiddown (Ireland) which manufactures machines for the production of shaped from wire or strip.

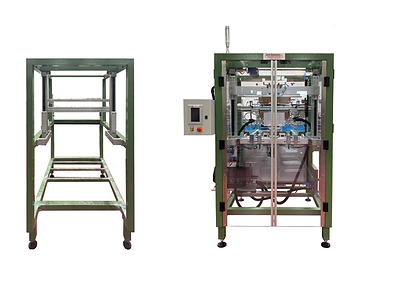

Over 60 different types of machines are designed and manufactured with more than 1000 packaging and automation lines, delivered to various industries around the world.

Our experience enables us to provide a 360-degree service for our customers including:

· feasibility studies for packaging lines and related automation;

· listing of machines and their accessories;

· contract definition;

· direct sales to your company;

· installation;

· training;

· technical assistance;

· spare parts sales.